Inspecting, Detecting & Testing Instruments

May 01, 2021

May 01, 2021

Debem traces its roots to 1975, has developed pumps for the chemical, textile, food, graphic, leather, ceramic, electronic, galvanic, paint, oil and sanitary industry. They have innovative and technologically advanced pumps built with materials and components resistant to aggressive conditions.

The main product range includes:

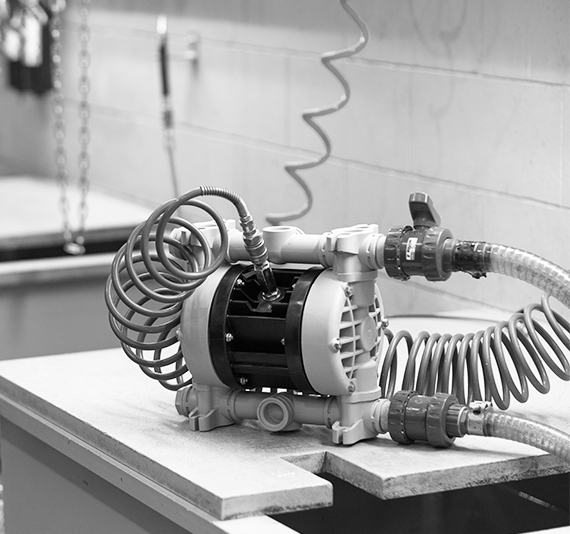

• Air-operated double diaphragm pumps

• Pulsation dampers

• Electric centrifugal pumps

• Drum transfer pumps

Their major application sectors are

• AUTOMOTIVE

• CERAMIC, STONE, MARBLE, GLASS, AND MINING INDUSTRY

• GALVANIC AND ELECTRONIC INDUSTRY

• GRAPHIC INDUSTRY

• TEXTILE AND LEATHER INDUSTRY

• PRODUCTION AND STORAGE OF BIODIESEL

• CHEMICAL INDUSTRY

• PACKING, GLUE, PAPER, AND PAPER MILLS

• MECHANICAL AND METALLURGIC INDUSTRY

• WATER AND SLUDGE TREATMENT

• PAINT INDUSTRY

• OIL & GAS

• GOLD PROCESSING INDUSTRY

All the pumps have ATEX and IECEx conformity. The CUBIC diaphragm mini pumps and the BOXER diaphragm pumps feature high levels of performance. Their considerable power and sturdiness render them ideal for pumping highly viscous liquids, even with suspended solids The pneumatic stall-prevention circuit guarantees a safe operation, without requiring lubricated air. These pumps have achieved unprecedented levels of versatility due to their dry self-priming capacity with a considerable suction head, the ability to fine-tune the speed without losses of pressure as well as the possibility of empty-running without suffering damage.

The vast range of construction materials allows us to select the best chemical compatibility with the fluid and/or the environment, without neglecting the operating temperature range. Their construction principle makes them ideally suited for demanding applications with high levels of humidity or in potentially explosive atmospheres (ATEX and IECEx certification).

Features include:

• Constructed in PP, PP+CF, PVDF, ECTFE, PTFE, ALUMINIUM, AISI 316 STAINLESS STEEL, AISI 316 L STAINLESS STEEL

• Use in explosive atmospheres (ATEX certification zone 1 – 2, IECEx certification)

• Suitable for demanding applications and in atmospheres with high levels of humidity

• Dry-running

• Dry self-priming

• Supply with non-lubricated air

• Patented stall-prevention pneumatic circuit

• Adjustable flow rate and head Fine adjustment of the speed at constant pressure

• Possibility of split manifolds (two suctions and two deliveries)

• Bench or ceiling installation

• Customisable positions

• Easy maintenance and parts replacement

• Excellent ratio between performance and costs

The diaphragms are the parts subjected to the greatest stresses during suction and pumping, whilst also having to resist the chemical attack and temperature of the liquid and the mechanical fatigue. Their correct assessment and selection is therefore of fundamental importance for the life of the diaphragm, as well as for the investment decisions and maintenance costs. A modern design process, destructing testing, as well as an in-depth analysis of the results have allowed Debem to develop the new generation LONG LIFE diaphragms. Thanks to their profile and construction shape, these products offer a larger working surface and improved redistribution of the load, reducing the stress and yield of the material to a minimum.

The ATEX - IECEx certified air-operated double diaphragm pumps, with their unique design and limited size, are ideally suited to be installed directly on industrial equipment for the chemical sector, to pump ink and paint, on printing machines, in oil circulation and in applications where moderate quantities of fluid must be pumped in small spaces. The CUBIC range includes the MIDGETBOX pump which is currently the smallest and highest performing pump on the market for the chemical sector.

• Product designed and constructed in Italy

• AIR-OPERATED DOUBLE DIAPHRAGM PUMPS PATENTED stall-prevention pneumatic circuit

• Operates with non-lubricated air

• Self-priming

• Dry operation

• ATEX certification for ZONE 1 - ZONE 2

• IECEx certification

• Adjustable operating speed

• Extremely versatile

• Suitable for pumping fluids in demanding applications

• Suitable for continuous use

Boxer type - Air-operated double diaphragm volumetric pumps, ATEX – IECEx certified, constructed in polypropylene or PVDF in the plastic version or in aluminium or AISI 316 L for the metal versions. BOXER pumps are ideal for pumping liquids with high apparent viscosity, even if containing suspended solids. The vast range of materials available for the parts in contact with the fluid, such as pump casings and manifolds, diaphragms, balls, ball seats and o-rings, makes them compatible with any type of fluid present on the market. They can be used in numerous applications such as the following industries: chemical, graphic, paint, galvanic, ceramic, naval, textile, leather, mechanical, oil and many more.

• Product designed and constructed in Italy

• PATENTED stall-prevention pneumatic circuit

• Operates with non-lubricated air

• Self-priming

• Dry operation

• ATEX certification for ZONE 1 - ZONE 2

• IECEx certification

• Adjustable operating speed

• Extremely versatile

• Suitable for pumping liquids with high viscosity and demanding applications

• Possibility of pumping fluids containing suspended solids

• Possibility of suspended installation

• Manifolds can be supplied with stainless steel reinforcement rings for pumps in PP – PP+CF – PVDF

• Nozzles available with clamp connections and DIN 11851 (only pumps in AISI 316)

• LONG LIFE profile diaphragms (available in different elastomers) for greater resistance and longer life

• Suitable for continuous use

The new FULL FLOW 502 pump is fitted with flaps instead of balls, which allow the passage of large-sized solids, reducing at the same time the crushing normally associated with the passage through balls and cages. Even though the maximum diameter for the passage of solids of 45 mm is not exclusive, the uniqueness for this type of pump lies in the maximum length of the solids: 600 mm. Similarly, the pump features an exclusive patented flap circuit positioned below, perpendicularly to the fluid chambers instead of being on axis. The fluid dynamics of this choice ensure that the solids transit outside the pump casing, following a linear path at a lower level to the pump. The maximum flow rate of the pump is about 530 liters per minute.

• Polypropylene casing

• Flap in EPDM and NBR, core in AISI 316 steel, always in contact with the fluid Can be split in suction and delivery

• Fittings: G 2”1/2 f or DN 65

• Air fitting: ½” Supply: min. 2 bar – max 4 bar

• Max. flow rate: 530 l/min

• Max. head: 40 m

• Max. dry suction: 3.5 m

• Max. flooded negative suction: 8 m

• Max. solids diameter: 45 mm

• Max. solid filaments length: 600 mm*

The EQUAFLUX dampers are used with fluids with a high apparent viscosity, also with large suspended solids.. They adapt automatically to the system conditions, without any manual adjustments or calibrations. The high capacity of minimizing pulsations, vibrations and water hammer renders this component ideal for protecting the system, providing a regular outlet flow. The vast range of construction materials allows us to select the best chemical compatibility with the fluid and/or the environment, without neglecting the correct temperature range. The dampers are also available for use in potentially explosive atmospheres (ATEX certification). The EQUAFLUX is operated by the same compressed air that drives the pump. The compressed air, introduced in the counter-pressure chamber (behind the diaphragm), creates a self-adjusting pneumatic damping cushion based on the pressure exerted by the pump.

Debem's magnetic drive centrifugal pumps are the ideal solution for numerous applications: laboratory machines, medical equipment, photographic developing machines, X-ray processes, silver recovery systems, graphics industry, heat exchangers, aquariums, water treatment, filtering systems, galvanic and chemical industry, and the transfer of acids and corrosive fluids. The DM pumps must be installed exclusively with the axis horizontal under the head. Suitable devices must be included to avoid the dry operation and the formation of vortexes and the possible suction of air.

The horizontal centrifugal pumps with a resin casing, are driven by a direct drive electric motor (max 3000 RPM) to transfer and/or empty liquids quickly, with flow rates from 6 to 75 m3/hour. Their unique open impeller design allows them to pump even very dirty fluids with an apparent viscosity up to 500 cps (at 20°C) and small-sized suspended solids. They are available in two versions with different internal mechanical seals, based on their use, TL (lip seal) and TS (bellows seal). They are driven by the impeller that, integrated with the shaft and the electric motor (direct drive), is rotated creating, due to centrifugal effect, suction on the central duct and delivery on the peripheral duct.

General Tech Services is the one and only distributor of Debem Products in the UAE. We are capable of providing Debem’s world-renowned products as well as services with the aid of our highly experienced staff base. Feel free to contact us for more info on Debem.

Debem traces its roots to 1975, has developed pumps for the chemical, textile, food, graphic, leather, ceramic, electronic, galvanic, paint, oil and sanitary industry. They have innovative and technologically advanced pumps built with materials and components resistant to aggressive conditions.

The main product range includes:

• Air-operated double diaphragm pumps

• Pulsation dampers

• Electric centrifugal pumps

• Drum transfer pumps

Their major application sectors are

• AUTOMOTIVE

• CERAMIC, STONE, MARBLE, GLASS, AND MINING INDUSTRY

• GALVANIC AND ELECTRONIC INDUSTRY

• GRAPHIC INDUSTRY

• TEXTILE AND LEATHER INDUSTRY

• PRODUCTION AND STORAGE OF BIODIESEL

• CHEMICAL INDUSTRY

• PACKING, GLUE, PAPER, AND PAPER MILLS

• MECHANICAL AND METALLURGIC INDUSTRY

• WATER AND SLUDGE TREATMENT

• PAINT INDUSTRY

• OIL & GAS

• GOLD PROCESSING INDUSTRY

All the pumps have ATEX and IECEx conformity. The CUBIC diaphragm mini pumps and the BOXER diaphragm pumps feature high levels of performance. Their considerable power and sturdiness render them ideal for pumping highly viscous liquids, even with suspended solids The pneumatic stall-prevention circuit guarantees a safe operation, without requiring lubricated air. These pumps have achieved unprecedented levels of versatility due to their dry self-priming capacity with a considerable suction head, the ability to fine-tune the speed without losses of pressure as well as the possibility of empty-running without suffering damage.

The vast range of construction materials allows us to select the best chemical compatibility with the fluid and/or the environment, without neglecting the operating temperature range. Their construction principle makes them ideally suited for demanding applications with high levels of humidity or in potentially explosive atmospheres (ATEX and IECEx certification).

Features include:

• Constructed in PP, PP+CF, PVDF, ECTFE, PTFE, ALUMINIUM, AISI 316 STAINLESS STEEL, AISI 316 L STAINLESS STEEL

• Use in explosive atmospheres (ATEX certification zone 1 – 2, IECEx certification)

• Suitable for demanding applications and in atmospheres with high levels of humidity

• Dry-running

• Dry self-priming

• Supply with non-lubricated air

• Patented stall-prevention pneumatic circuit

• Adjustable flow rate and head Fine adjustment of the speed at constant pressure

• Possibility of split manifolds (two suctions and two deliveries)

• Bench or ceiling installation

• Customisable positions

• Easy maintenance and parts replacement

• Excellent ratio between performance and costs

The diaphragms are the parts subjected to the greatest stresses during suction and pumping, whilst also having to resist the chemical attack and temperature of the liquid and the mechanical fatigue. Their correct assessment and selection is therefore of fundamental importance for the life of the diaphragm, as well as for the investment decisions and maintenance costs. A modern design process, destructing testing, as well as an in-depth analysis of the results have allowed Debem to develop the new generation LONG LIFE diaphragms. Thanks to their profile and construction shape, these products offer a larger working surface and improved redistribution of the load, reducing the stress and yield of the material to a minimum.

The ATEX - IECEx certified air-operated double diaphragm pumps, with their unique design and limited size, are ideally suited to be installed directly on industrial equipment for the chemical sector, to pump ink and paint, on printing machines, in oil circulation and in applications where moderate quantities of fluid must be pumped in small spaces. The CUBIC range includes the MIDGETBOX pump which is currently the smallest and highest performing pump on the market for the chemical sector.

• Product designed and constructed in Italy

• AIR-OPERATED DOUBLE DIAPHRAGM PUMPS PATENTED stall-prevention pneumatic circuit

• Operates with non-lubricated air

• Self-priming

• Dry operation

• ATEX certification for ZONE 1 - ZONE 2

• IECEx certification

• Adjustable operating speed

• Extremely versatile

• Suitable for pumping fluids in demanding applications

• Suitable for continuous use

Boxer type - Air-operated double diaphragm volumetric pumps, ATEX – IECEx certified, constructed in polypropylene or PVDF in the plastic version or in aluminium or AISI 316 L for the metal versions. BOXER pumps are ideal for pumping liquids with high apparent viscosity, even if containing suspended solids. The vast range of materials available for the parts in contact with the fluid, such as pump casings and manifolds, diaphragms, balls, ball seats and o-rings, makes them compatible with any type of fluid present on the market. They can be used in numerous applications such as the following industries: chemical, graphic, paint, galvanic, ceramic, naval, textile, leather, mechanical, oil and many more.

• Product designed and constructed in Italy

• PATENTED stall-prevention pneumatic circuit

• Operates with non-lubricated air

• Self-priming

• Dry operation

• ATEX certification for ZONE 1 - ZONE 2

• IECEx certification

• Adjustable operating speed

• Extremely versatile

• Suitable for pumping liquids with high viscosity and demanding applications

• Possibility of pumping fluids containing suspended solids

• Possibility of suspended installation

• Manifolds can be supplied with stainless steel reinforcement rings for pumps in PP – PP+CF – PVDF

• Nozzles available with clamp connections and DIN 11851 (only pumps in AISI 316)

• LONG LIFE profile diaphragms (available in different elastomers) for greater resistance and longer life

• Suitable for continuous use

The new FULL FLOW 502 pump is fitted with flaps instead of balls, which allow the passage of large-sized solids, reducing at the same time the crushing normally associated with the passage through balls and cages. Even though the maximum diameter for the passage of solids of 45 mm is not exclusive, the uniqueness for this type of pump lies in the maximum length of the solids: 600 mm. Similarly, the pump features an exclusive patented flap circuit positioned below, perpendicularly to the fluid chambers instead of being on axis. The fluid dynamics of this choice ensure that the solids transit outside the pump casing, following a linear path at a lower level to the pump. The maximum flow rate of the pump is about 530 liters per minute.

• Polypropylene casing

• Flap in EPDM and NBR, core in AISI 316 steel, always in contact with the fluid Can be split in suction and delivery

• Fittings: G 2”1/2 f or DN 65

• Air fitting: ½” Supply: min. 2 bar – max 4 bar

• Max. flow rate: 530 l/min

• Max. head: 40 m

• Max. dry suction: 3.5 m

• Max. flooded negative suction: 8 m

• Max. solids diameter: 45 mm

• Max. solid filaments length: 600 mm*

The EQUAFLUX dampers are used with fluids with a high apparent viscosity, also with large suspended solids.. They adapt automatically to the system conditions, without any manual adjustments or calibrations. The high capacity of minimizing pulsations, vibrations and water hammer renders this component ideal for protecting the system, providing a regular outlet flow. The vast range of construction materials allows us to select the best chemical compatibility with the fluid and/or the environment, without neglecting the correct temperature range. The dampers are also available for use in potentially explosive atmospheres (ATEX certification). The EQUAFLUX is operated by the same compressed air that drives the pump. The compressed air, introduced in the counter-pressure chamber (behind the diaphragm), creates a self-adjusting pneumatic damping cushion based on the pressure exerted by the pump.

Debem's magnetic drive centrifugal pumps are the ideal solution for numerous applications: laboratory machines, medical equipment, photographic developing machines, X-ray processes, silver recovery systems, graphics industry, heat exchangers, aquariums, water treatment, filtering systems, galvanic and chemical industry, and the transfer of acids and corrosive fluids. The DM pumps must be installed exclusively with the axis horizontal under the head. Suitable devices must be included to avoid the dry operation and the formation of vortexes and the possible suction of air.

The horizontal centrifugal pumps with a resin casing, are driven by a direct drive electric motor (max 3000 RPM) to transfer and/or empty liquids quickly, with flow rates from 6 to 75 m3/hour. Their unique open impeller design allows them to pump even very dirty fluids with an apparent viscosity up to 500 cps (at 20°C) and small-sized suspended solids. They are available in two versions with different internal mechanical seals, based on their use, TL (lip seal) and TS (bellows seal). They are driven by the impeller that, integrated with the shaft and the electric motor (direct drive), is rotated creating, due to centrifugal effect, suction on the central duct and delivery on the peripheral duct.

General Tech Services is the one and only distributor of Debem Products in the UAE. We are capable of providing Debem’s world-renowned products as well as services with the aid of our highly experienced staff base. Feel free to contact us for more info on Debem.

[Back to Blog ]

Al Belad General Tech

Near McDonalds,

Block 6 East Ahmadi Behind Co-operative,

Kuwait

Email: mathews@generaltechkuwait.com

Website: www.generaltechkuwait.com

© 2024 Copyright ® All Rights Reserved. General Tech Services LLC.